In the blazing heat of Farmville, where the wheat swayed with the wind and the sun blazed on the corn, a brewing storm was underway. Once a blooming farming community with a large population, the community dwindled down to a hybrid rural municipality with 10,000 residents who focused on both renewable and non-renewable resources to extend their aeration wastewater treatment plant.

However, that wastewater plant was beyond repair. Its aging materials, built decades ago, had been a vital piece of Farmville, but was now more of a liability and in need of a major upgrade.

The townsfolk had always relied on the skilled operators to run the plant full time, maintaining discharge compliance. But as seasons passed, the operators grew older, leaving the treatment plant without many experienced workers. The burden of the plant grew heavier as even the young folk in town had their sights set on tech jobs or jobs in large metro areas, rather than handling an aging wastewater treatment plant in a small city.

With new state incentives, the town was successful in adding a new battery manufacturing plant to their community. With this installment, the town was expecting their population to grow significantly, resulting in a greater reliance on the declining wastewater plant.

In order to support the future of Farmville, the city’s head engineer, Jack Mason, knew he had to do something fast. He began searching vigorously for solutions that would benefit the community. Jack wondered where he could find a solution that was simple, low cost, and robust; a solution that could replace the current wastewater plant and expand the facility without requiring as much manpower.

Eager to find an answer, the engineer decided to attend the state water conference. Walking by the wide array of booths, Jack suddenly stumbled upon his old friend–Ryan Blake–who was a city manager of a smaller, nearby city: Sunnydale. The two friends decided to catch up over lunch, while confiding over the troubles they faced.

“Farmville has great potential, but our wastewater plant will not accommodate the population growth when this new battery plant goes live, Ryan,” Jack revealed, distraught of the current environmental situation of their town.

“Well, why don’t you just ask Aerobe?” Ryan exclaimed.

“Who?”.

“Aerobe, from BioMicrobics! They have a booth back at the conference. Why don’t we head there now?” Ryan explained, as the two friends hopped in the car and made their way back to the convention.

Jack nervously approached the booth, hoping his problem could be answered. As he walked in, his eyes fell upon the head-man, Aerobe, who was handing out brochures, chatting with on-goers, and giving out goodies.

As Jack approached, Aerobe gave him a charming smile. “Hello there! I’m Aerobe, what can I help you with?”

Jack greeted the specialist and confided in his wastewater treatment challenge. “Farmville is in need of a new water waste treatment plant. Something quick and easy. Something that doesn’t require much manpower,” Aerobe nodded his head, “We need equipment that has both endurance and resilience. What do you recommend?”.

“I’m so glad you asked, Jack! BioMicrobics has many great treatments to offer. For your case, being a growing community in need of something simple and manageable, I recommended a modern MacroFITT/MyFAST® system,” Aerobe declared.

“A what?”

Aerobe chuckled, handing curious Jack a brochure of the unique system.

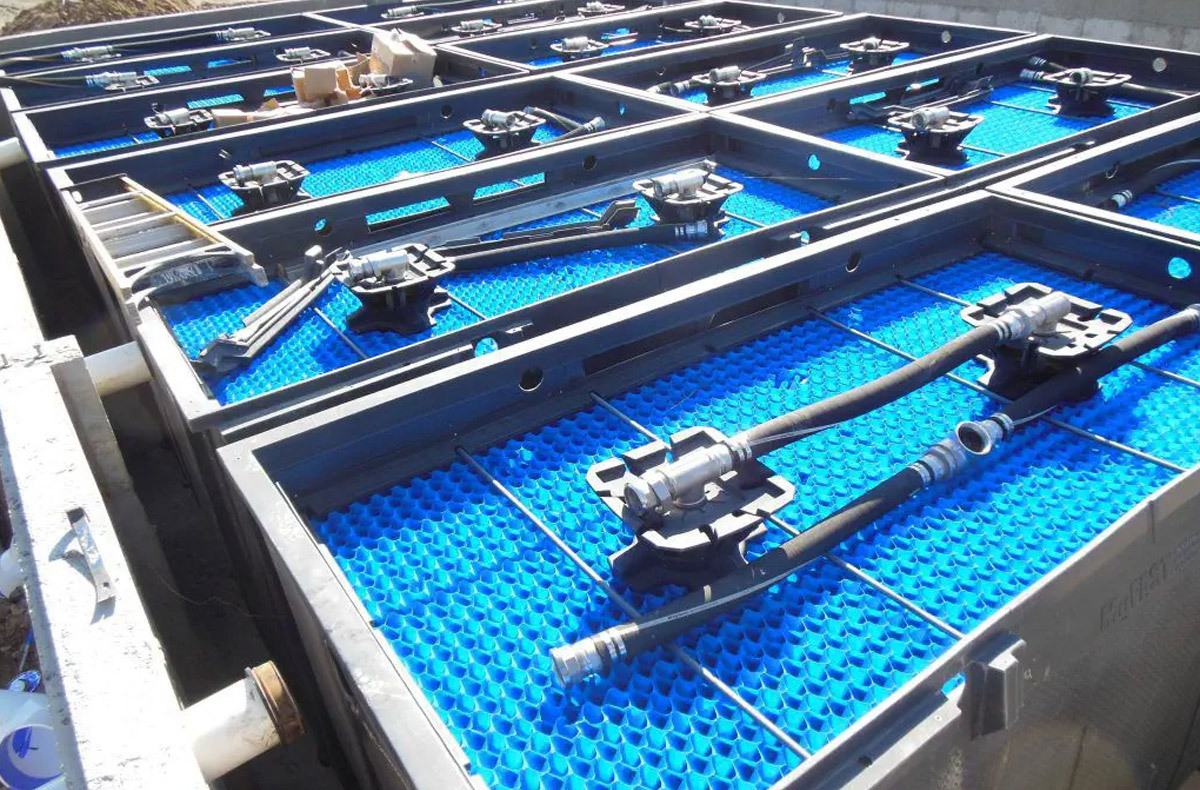

“A MacroFITT/MyFAST® treatment system! This equipment helped to treat wastewater from small communities and municipalities, with minimal maintenance. It has many advantages as it doesn’t require a full time operator, it’s fully submerged and permanent, it has no moving parts or anything that can corrode under water, and achieves effluent standards and nutrient reduction,” Aerobe explained.

Jack, fascinated by the multipurpose treatment, began looking through the brochure. He stumbled upon a picture of the machine, “How exactly does this work?”

“I’m so glad you asked! The first step consists of settling the first tank compartment, designated as a primary clarifier. Next, the wastewater goes through a screening process, where it removes the trash and grit, allowing the water upstream. Then, the wastewater becomes treated with the MyFAST/ MacroFITT modules, helping to treat the water with oxygen being delivered. Later, the settled biosolids in the treatment zone are transferred to another tank, finally allowing for the treated water to be discharged out of the system with gravity!” Aerobe explained graciously.

Jack felt as if all of the puzzle pieces were finally aligning together. He had found the solution he had been looking for all along–a treatment that would efficiently help his community!

With the help of Aerobe, Farmville decided to incorporate a modern MacroFITT 140 treatment system from BioMicrobics at its ribbon cutting ceremony. The community gathered around this treatment plant, with the energy being high, and the crowd cheering loud.

“We didn’t just build a wastewater treatment plant; we built a bridge to our future!” Jack exclaimed, admiring the new installation with the help of Aerobe. And as Farmville prepared to welcome its new residents from the battery plant, it stood not just ready to manage its waste but to embrace a vibrant, sustainable future—a community proud of its roots and eager for the adventures yet to come