AIA Engineering Ltd.

| Location: | Ahmedabad, India |

| Project Name: | AIA Engineering Ltd. Odhav Plant |

| Installation Date: | 29th May 2018 |

| Project Size (System Capacity): | 40 KLD with Nitrogen removal |

| Customer: | AIA Engineering Ltd. |

| Designer: | BioWater Treatment Systems LLP (Vadodara, India) |

| Manufacturer: | BioMicrobics Inc. |

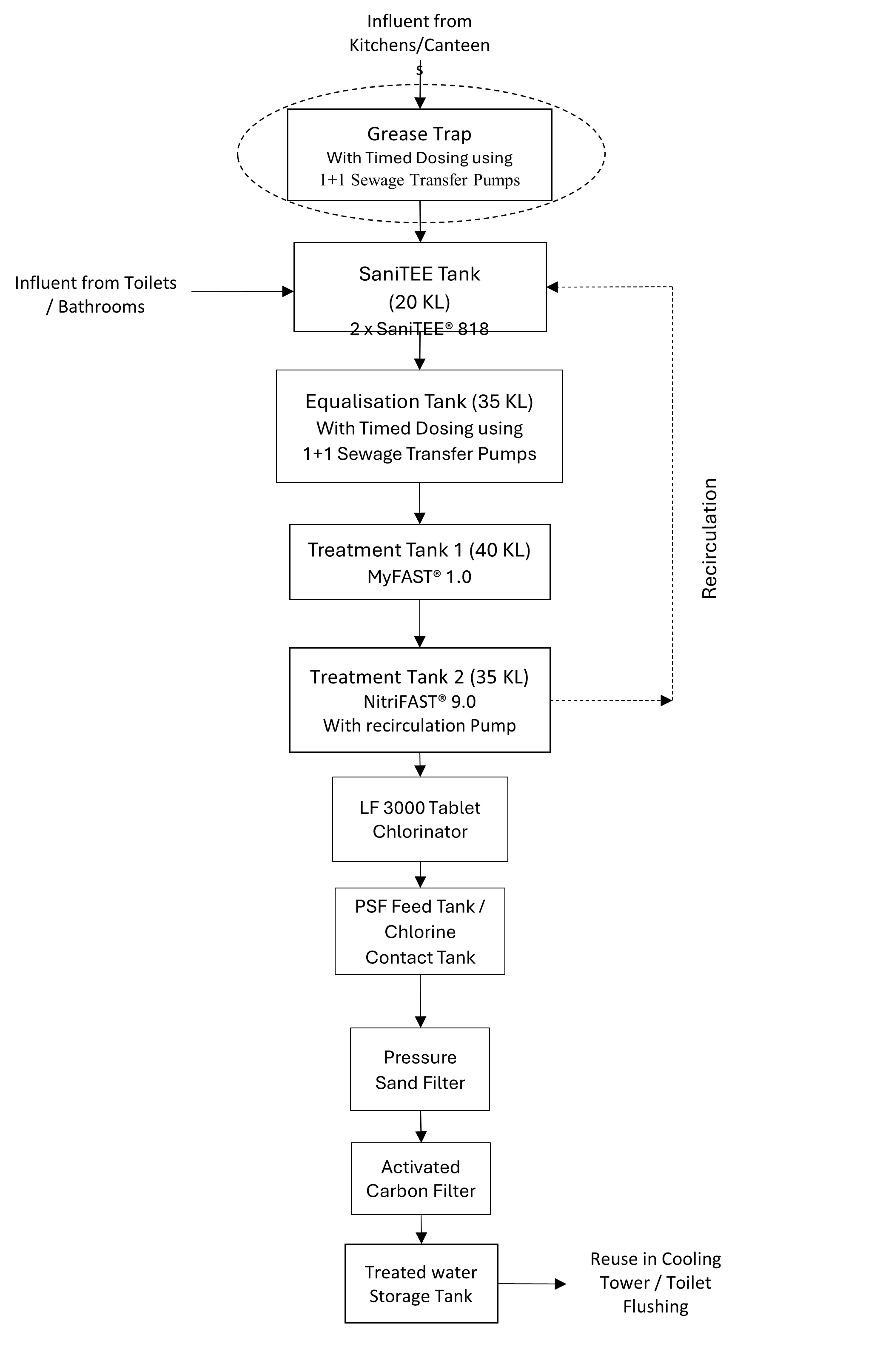

Equipment:

- 2 units of SaniTEE® 818

- 1 unit of MyFAST® 1.0

- 1 unit of NitriFAST® 9.0

- Disinfection – LF 3000 Tablet Chlorinator

- Pressure Sand Filter

- Activated Carbon Filter

- 2 x 0.37 kW mono-block Recirculation pumps

- 2 x 1.2 kW Grundfos Sewage Transfer pumps (in Equalization Tank)

- 2 x 0.37 kW Sewage Transfer pumps (in Grease Trap)

Background

AIA Engineering is a large foundry with several plants. They specialise in grinding media and lining for the cement mining and allied industries. AIA’s unit no. 13 is situated in a dense industrial area. Unable to cope with the sewage generated from the industries in the area, the local authorities notified large companies to install treatment plants and banned any discharge of sewage into the municipal sewerage system.

Challenges

Space:

Being an old, established factory, there were limited options for the location of the STP. Finally, the location chosen was the scrapyard adjacent to the main worker’s toilet and changing room. The wastewater from the canteen would be pumped to the STP after being collected in an oil and grease separator.

Water Quality:

The foundry uses sand with polymeric binders to make the moulds for the castings. After the castings are removed from the mould, the burrs and mould lines need to be ground down with power tools. Both sand and iron filings get on the clothes, hands and faces of workers which then find their way into the wastewater. As a result the nature of the wastewater is considerably different to domestic wastewater.

Sewage Characteristics:

| Parameters | Influent | Effluent from FAST® | Effluent after PSF-ACF |

| BOD5 | <300 ppm | <30 ppm | <10 |

| COD | <600 ppm | <80 ppm | <50 |

| TSS | <600 ppm | <30 ppm | <10 |

| pH | 6.0 – 9.0 | 6.5 – 8.0 | 6.5 – 8.0 |

| Oil & Grease | <40 ppm | <5 ppm | Nil |

| NH4-N | <55 ppm | <5 ppm | <5 ppm |

| Total Nitrogen (TKN) | <80 ppm | <10 ppm | <10 ppm |

| Fecal Coliform | <100 MPN/100ml |

(BOD = Biological Oxygen Demand; COD = Chemical Oxygen Demand; TSS = Total Suspended Solids)

Treated Water Reuse:

The treated water is primarily used for Cooling Tower Make-up and to water the garden created above the treatments system.

System:

Result

AIA Engineering was able to conform to the strict treatment norms specified by the Pollution Control Board. All the wastewater generated at the plant is now treated by the treatment system installed by BioWater and used for cooling tower make-up water and gardening. Not only has AIA stopped discharging wastewater, it has reduced its consumption of fresh water and was even able to create a green space.

Website: https://aiaengineering.com/at-a-glance/

Google Location: https://maps.app.goo.gl/XpL6UcUZsYrBSWfP7